PRODUCTEN

BASF PSU 6010|Chemical Resistance PSU Polymer For Sanitary

Productconstructie

What is PSU Polymer

In the field of precision manufacturing, purchasers not only focus on the performance indicators of materials, but also care whether they can meet the usage requirements in complex environments for a long time. psu polymer (polysulfone) has become a commonly used material for medical devices, electronic components and bathroom accessories due to its molecular stability and reliable engineering properties. Basf PSU 6010, as a representative among them, not only has the advantages of heat resistance and chemical resistance, but also can provide definite guarantees for purchasers in terms of dimensional stability and electrical insulation.

01 | Material Advantages

Long-term tolerance: It can maintain a stable structure even in acidic, alkaline, cleaning agents and hot water environments.

Mechanical reliability: Tensile strength 75 MPa, modulus 2550 MPa, suitable for load-bearing structural components.

Environmental adaptability: Low shrinkage rate (0.72-0.77%), low water absorption rate (0.3%), ensuring that the parts maintain precision under humidity or temperature differences.

Safety insulation: Volume resistance 1E15 Ω·cm, insulation strength 37 kV/mm, suitable for electrical applications.

Thermische stabiliteit: The heat distortion temperature is 177°C, and it can maintain its shape unchanged in high-temperature applications.

02 | Basf Ultrason®S 6010 psu polymer

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Verlenging | Opbrengst 23°C | ISO527 | 5.7 | % | |||

| Izod Notch-impact | 23°C | ISO180 | 6.0 | kJ/m² | |||

| Izod Notch-impact | -30°C | ISO180 | 6.5 | kJ/m² | |||

| Treksterkte | Opbrengst 23°C | ISO527 | 75.0 | MPa | |||

| Trekmodulus | 23°C | ISO527 | 2550 | MPa | |||

| Charpy Un-notch-impact | 23°C | ISO179 | Let op | ||||

| Charpy Un-notch-impact | -30°C | ISO179 | Let op | ||||

| Charpy Notch-impact | 23°C | ISO179 | 6.0 | kJ/m² | |||

| Charpy Notch-impact | -30°C | ISO179 | 6.5 | kJ/m² | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| HDT | Niet-gegloeid 1,8 MPa | ISO75 | 177 | °C | |||

| CLE | Stroom | 5.3E-5 | cm/cm/°C | ||||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Wateropname | 23°C Verzadiging | ISO62 | 0.80 | % | |||

| Wateropname | 23°C 50RH Balance | ISO62 | 0.30 | % | |||

| Krimp | Stroom | ISO294 | 0.72 | % | |||

| Krimp | xFlow | ISO294 | 0.77 | % | |||

| Dikte | ISO1183 | 1.23 | g/cm³ | ||||

| Smeltindex | 360°C 10kg | ISO1133 | 30 | cm³/10min | |||

| Elektrische eigenschappen | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CTI | EN 60112 | 125 | V | ||||

| Diëlektrische constante | 1 MHz | EN 60250-norm | 3.40 | ||||

| Diëlektrische constante | 100Hz | EN 60250-norm | 3.50 | ||||

| Volumeweerstand | IEC 60093 | 1E15 | Ω.cm | ||||

| Diëlektrische sterkte | IEC 60243 | 37 | kv/mm | ||||

| Dissipatiefactor | 1 MHz | EN 60250-norm | 0.0071 | ||||

| Dissipatiefactor | 100Hz | EN 60250-norm | 0.0011 | ||||

| Oppervlakteweerstand | IEC 60093 | 1E15 | Ω | ||||

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Hardheid van de kogelindrukking | ISO2039 | 135 | MPa | ||||

03 | Processing and process compatibility

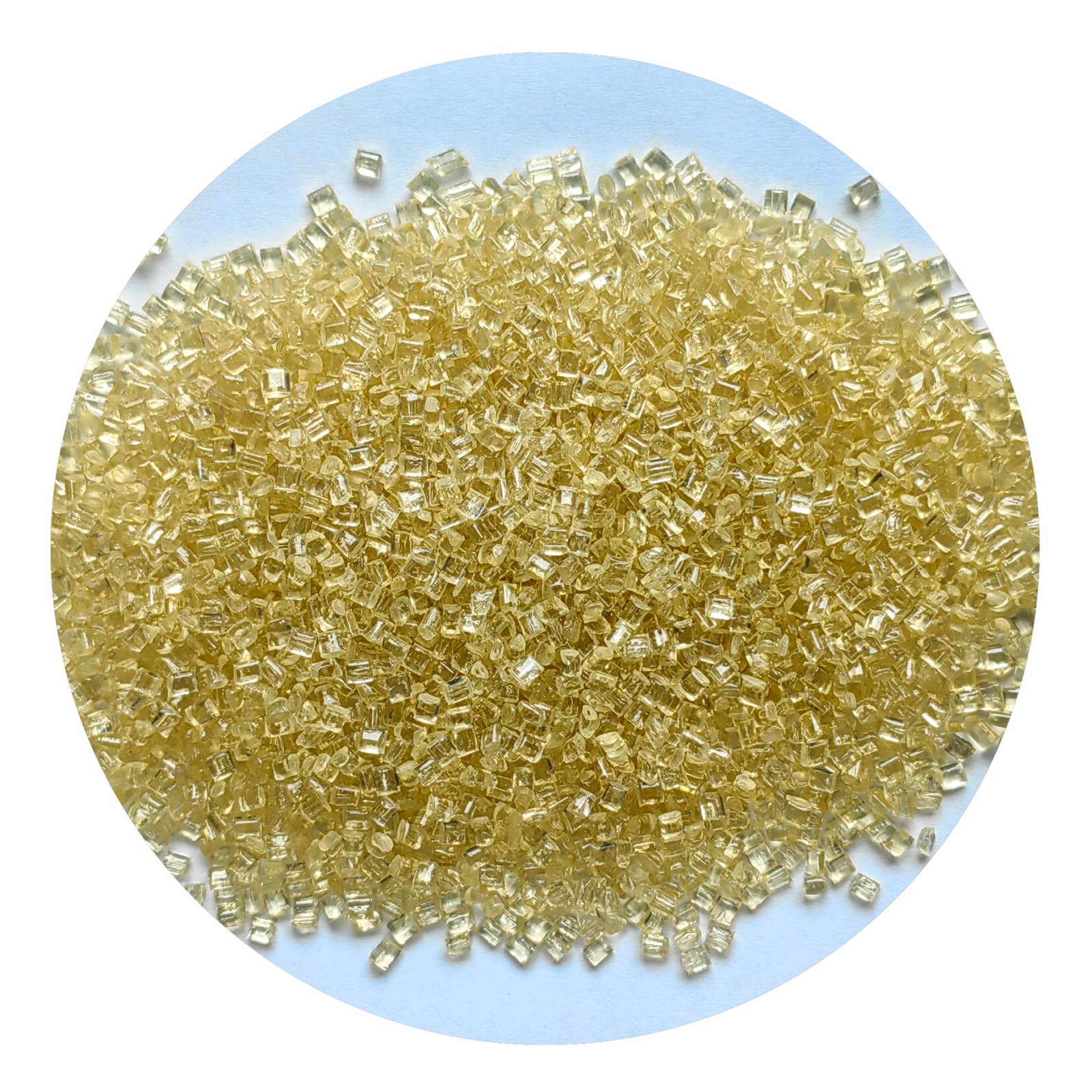

PSU 6010 is supplied in granular form and is suitable for injection molding and extrusion.

・Injection molded parts: Medical shells, bathroom components, with complex shapes but requiring long-term reliability.

・Extruded products: film materials, tubes and coatings, with higher requirements for dimensions and surface stability.

Its melt index is 30 cm³/10min (360°C/10kg), achieving a balance between processing fluidity and product accuracy.

04 | Application direction

Combined with its performance, the application value of psu polymer is mainly reflected in:

・Water treatment membranes and diaphragms: Chemical resistance ensures filtration efficiency and service life.

・High-end bathroom fixtures: Reliable even after long-term contact with hot water and cleaning agents.

・Medical and electronic protective layers: Enhance equipment safety and durability.

・Electrical insulation components: Ensure safe operation in areas such as connectors and insulation brackets.

05 | Industry trends

Rather than merely emphasizing "high performance", what deserves more attention from purchasers is:

・Cost-effectiveness: PSU often outperforms cheaper alternative materials in terms of durability and life cycle.

・Alternative solution: In response to the demand for lightweighting of some metal and glass products, PSU offers more flexible design and processing space.

・Compliance: Under the increasingly strict material standards in the medical and electronic industries, psu polymer has become a stable choice.

06 | Veelgestelde vragen (FAQ)

Q1: What are the differences between PSU 6010 and common PC or PPO?

A1: PSU is more heat-resistant and chemical-resistant, and also has better dimensional stability, making it suitable for long-term use scenarios.

Q2: What details should be noted during processing?

A2: The temperature needs to be controlled at around 360° C. In the mold design, the shrinkage rate of the material should be taken into consideration.

Q3: Can it be in long-term contact with hot water or cleaning agents?

A3: Yes, that's exactly why PSU 6010 is widely adopted in bathrooms and medical fields.

Q4: How to ensure a stable supply?

A4: Juyuan provides global supply chain guarantee to ensure the continuous delivery of psu polymer materials.

Q5: What if I'm not sure if it's suitable for my project?

A5: You can contact the Juyuan technical team to obtain professional selection advice and alternative solutions.

07 | Similar recommendations

In addition to BASF PSU 6010, purchasers can also pay attention to:

| Fabrikant | Productmodel | Value Summary | Description | Dikte | Melt Flow Index | Treksterkte | Verlenging | Krimp | Smelttemperatuur | Trekmodulus | Heat Distortion Temperature | Notched Izod Impact | Coefficient of Linear Expansion |

| BASF | 6010 NAT | Viscosity: High ViscosityNotched Impact: 6 kJ/m² | Material Properties: Unreinforced • Toughness • Chemical Resistance | 1.23 g/cm³ | 30 cm³/10min | 75 MPa | 5.70% | 0.72% | 330~390 °C | 2550 MPa | 177 °C | 6 kJ/m² | 5.3E-5 cm/cm/°C |

08 | Why choose Juyuan

・Global procurement and delivery capabilities reduce supply chain risks

・Provide multiple categories of psu polymer options to cover the requirements of different working conditions

・One-on-one material selection support reduces the trial-and-error costs for the purchasing party

【Gerelateerde aanbevelingen】

BASF Ultrason® S 3010 | Heat-Resistant Polysulfone for Labware Meer informatie>

BASF PSU 2010 | High Flowability PSU Polysulfone for Household Meer informatie>

Plastic Raw Materials Supply Guide | For Household Appliance Manufacturing Meer informatie>