PRODUCTEN

ABS PA-746: Veelzijdige, hoogwaardige technische kunststof

Productconstructie

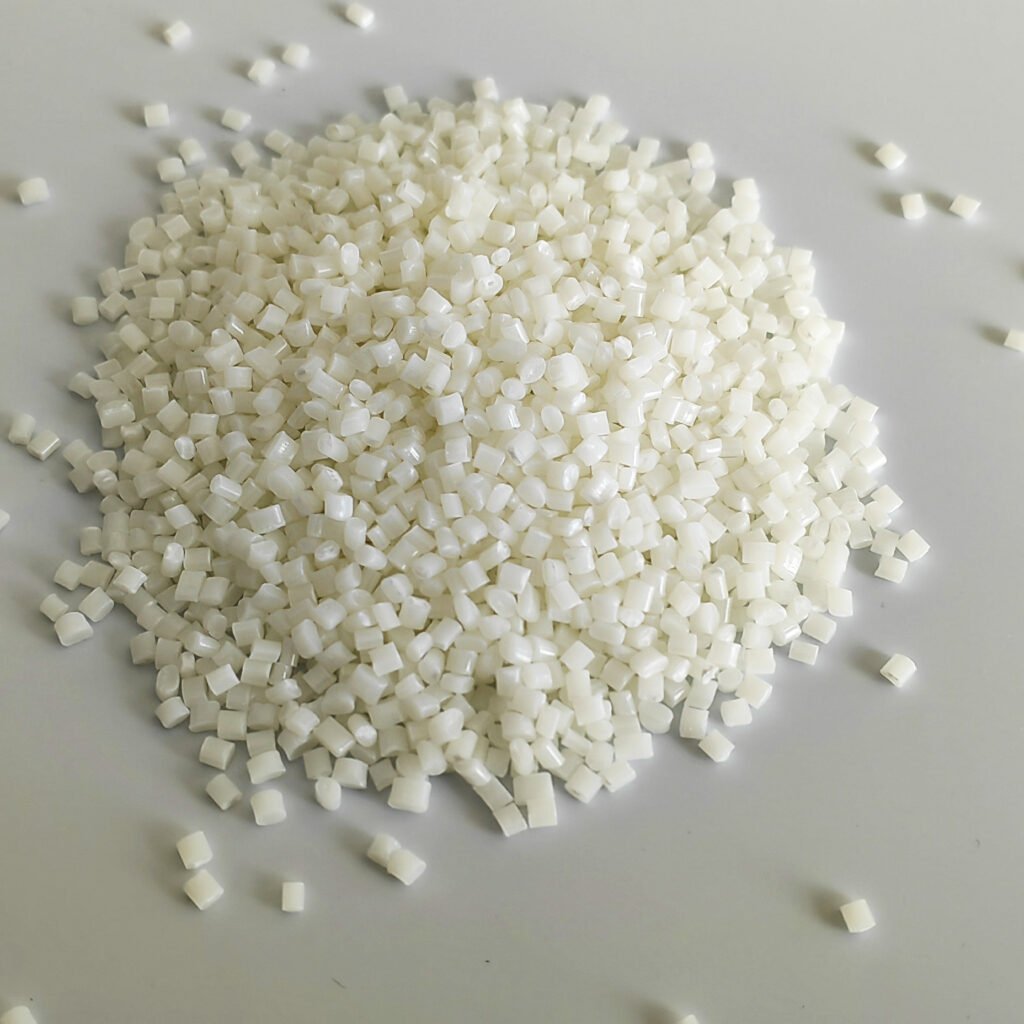

ABS PA-746 plastic pellets are an injection molding grade engineering plastic widely used in applications requiring high fluidity and impact strength. This material is processed through injection molding techniques and is particularly suitable for producing components with large surface areas or thin-walled structures, offering excellent surface quality and high molding precision. Its high fluidity ensures smooth filling in complex molds, reducing product defects and accommodating diverse shaping requirements.

In terms of material properties, ABS PA-746 exhibits superior impact resistance and high rigidity, ensuring the durability of products during use. Additionally, the incorporation of lubricants and release agents in the material significantly enhances processing performance, reduces friction during production, improves demolding efficiency, and shortens the production cycle.

Due to its outstanding properties, ABS PA-746 is extensively utilized across various sectors. In the automotive industry, it is commonly used for manufacturing parts such as motorcycle side covers and fenders. In office equipment, it is primarily used for the casings of printers and photocopiers. In the home appliance sector, it is widely applied in the injection molding of casings for televisions, air conditioners, and washing machines. With its excellent mechanical properties, processing performance, and cost-effectiveness, ABS PA-746 has become a commonly used engineering plastic in multiple industries.

| Ontvlambaarheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Vlam | Waardering Alle kleuren 1,5 mm | UL94 | HB | ||||

| Vlam | Waardering Alle kleuren 3,0 mm | UL94 | HB | ||||

| Hardheid | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Rockwell | Hardheid R (schaal) | ASTM D785 | 118 | ||||

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Charpy | Kerfslag 23°C | ISO179 | 30 | kJ/m² | |||

| Charpy | Kerfimpact -30°C | ISO179 | 14 | kJ/m² | |||

| Verlenging | 6 mm/minuut | ASTM D638 | 30 | % | |||

| Verlenging | 50 mm/minuut | ISO527 | 30 | % | |||

| Buigzaam | Sterkte 2,8 mm/min | ASTM D790 | 650 | kg/cm² | |||

| Buigzaam | Sterkte 2,0 mm/min | ISO178 | 60 | MPa | |||

| Buigzaam | Modulus 2,8 mm/min | ASTM D790 | 22000 | kg/cm² | |||

| Buigzaam | Modulus 2,0 mm/min | ISO178 | 1.8 | GPa | |||

| Izod | Kerf Impact 23°C 6,4mm | ASTM D256 | 26 | kg-cm/cm | |||

| Izod | Kerf Impact 23°C 3,2mm | ASTM D256 | 32 | kg-cm/cm | |||

| Izod | Kerfslag 23°C | ISO180 | 28 | kJ/m² | |||

| Izod | Kerf Impact -30°C | ISO180 | 12 | kJ/m² | |||

| Treksterkte | Sterkte opbrengst 6mm/min | ASTM D638 | 415 | kg/cm² | |||

| Treksterkte | Sterkte Opbrengst 50 mm/min | ISO527 | 39 | MPa | |||

| Treksterkte | Sterktebreuk 50mm/min | ISO527 | 29 | MPa | |||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | 23°C | ASTM D792 | 1.03 | g/cm³ | |||

| Dikte | 23°C | ISO1183 | 1.03 | g/cm³ | |||

| Smelten | Index 200°C 5kg | ASTM D1238 | 3.0 | g/10min | |||

| Smelten | Index 220°C 10kg | ISO1133 | 29 | cm³/10min | |||

| Krimp | ISO294 | 0.4~0.7 | % | ||||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| CLE | ISO11359 | 9.2E-5 | cm/cm/°C | ||||

| HDT | Gegloeid 1,8 MPa | ASTM D648 | 95 | °C | |||

| HDT | Niet-gegloeid 1,8 MPa | ASTM D648 | 85 | °C | |||

| HDT | Niet-gegloeid 1,8 MPa | ISO75 | 82 | °C | |||

| HDT | Gegloeid 1,8 MPa | ISO75 | 96 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 10N | ASTM D1525 | 105 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 10N | ISO306 | 103 | °C | |||

| Vicat | Verzachtingstemperatuur 50°C/uur 50N | ISO306 | 94 | °C | |||

| UL | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Boog | Weerstand | ASTM D495 | 6 | BV | |||

| Vergelijkend | Trackingindex | EN 60112 | 0 | BV | |||

| HAI | ALLE 1,5 mm | UL746A | 0 | BV | |||

| HAI | ALLE 3,0 mm | UL746A | 0 | BV | |||

| HVTR | UL746A | 2 | BV | ||||

| HWI | ALLE 1,5 mm | UL746A | 4 | BV | |||

| HWI | ALLE 3,0 mm | UL746A | 3 | BV | |||

| RTI | Elektrisch ALLE 1,5 mm | UL 746B | 85 | °C | |||

| RTI | Elektrisch ALLE 3,0 mm | UL 746B | 85 | °C | |||

| RTI | Imp ALLE 1,5 mm | UL 746B | 80 | °C | |||

| RTI | Imp ALLE 3,0 mm | UL 746B | 80 | °C | |||

| RTI | Str ALLE 1,5 mm | UL 746B | 85 | °C | |||

| RTI | Str ALLE 3,0 mm | UL 746B | 85 | °C | |||

| UL | Vlamwaarde ALLES 1,5 mm | UL94 | HB | ||||

| UL | Vlamclassificatie ALLES 3,0 mm | UL94 | HB | ||||

| Volume | Weerstand | ASTM D257 | 1E+16 | Ω.cm | |||