PRODUCTEN

Introductie tot Metallocene Lineaire Lage Dichtheid Polyethyleen 1327MD

Productconstructie

MLLDPE 1327MD Inleiding

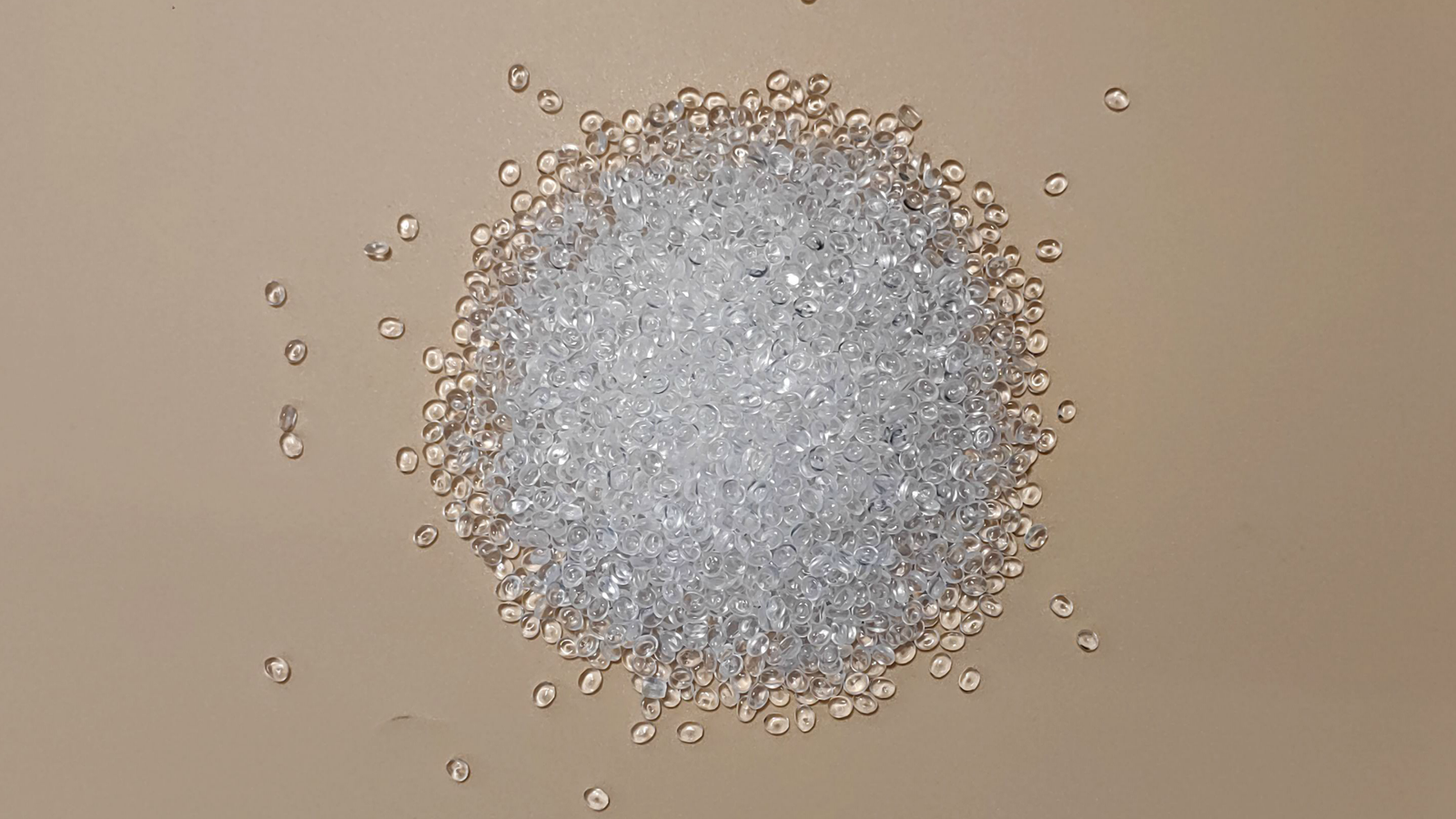

mLLDPE 1327MD plastic pellets zijn een hoogwaardig metalloceen lineair lagedichtheidspolyethyleen (mLLDPE) copolymeer met een natuurlijke uitstraling, ontworpen voor blaasvormprocessen. De materiaaleigenschappen omvatten filmkwaliteit en blaasvormkwaliteit en voldoen aan de normen voor contact met voedingsmiddelen. De toevoeging van openingsagentia en een zes-koolstofcopolymeer verbetert de verwerkingseigenschappen en mechanische sterkte.

1. De eigenschappen van MLLDPE 1327MD

Het metallocene LLDPE-materiaal wordt gekenmerkt door een hoge modulus en hoge taaiheid, waardoor het uitstekend geschikt is voor folietoepassingen. Het biedt een goede flexibiliteit, scheurweerstand en perforatieweerstand. De uitstekende barrière-eigenschappen maken het veelgebruikt in voedsel- en industriële verpakkingen, waaronder box lining bags, barrier food packaging, broodzakken, verzegelde verpakkingen, rechtopstaande zakken, vuilniszakken, ritssluitingszakken en krimpfolies.

2. Toepassingen van lineair lagedichtheidspolyethyleen van metallocene

Daarnaast worden aan mLLDPE1327MD-korrels openingsstoffen, hittestabilisatoren, vormadditieven en glijverbeteraars toegevoegd om de verwerkingsprestaties te optimaliseren, de oppervlaktegladheid van de folie te verbeteren en het gebruiksgemak van de folie te vergroten. Hierdoor is het een ideale keuze voor hoogwaardige verpakkingsmaterialen.

3、Metalloceen LLDPE 1327MD-parameters

| Mechanisch gedrag | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Elmendorf | Scheursterkte Stroom | ASTM D1922 | 190 | G | |||

| Elmendorf | Scheursterkte xFlow | ASTM D1922 | 450 | G | |||

| Verlenging | Stroomonderbreking | ASTM D882 | 560 | % | |||

| Verlenging | xFlow-pauze | ASTM D882 | 620 | % | |||

| Vallen | Gewicht Impactsterkte | ASTM D1709 | 140 | G | |||

| Lek | Weerstand | INTERNE METHODE | 38 | N | |||

| Lek | Weerstand | INTERNE METHODE | 1.7 | J | |||

| Snijkant | Modulus 1%-stroom | ASTM D882 | 310 | MPa | |||

| Snijkant | Modulus 1% xFlow | ASTM D882 | 330 | MPa | |||

| Treksterkte | Sterkte Stroom Opbrengst | ASTM D882 | 13 | MPa | |||

| Treksterkte | Sterkte xFlow Opbrengst | ASTM D882 | 14 | MPa | |||

| Treksterkte | Krachtstroompauze | ASTM D882 | 47 | MPa | |||

| Treksterkte | Sterkte xFlow Break | ASTM D882 | 39 | MPa | |||

| Optische prestaties | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Glans | 45° | ASTM D2457 | 25 | ||||

| Nevel | ASTM D1003 | 26 | % | ||||

| Fysieke eigendom | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Dikte | ASTM D1505 | 0.927 | g/cm³ | ||||

| Smelten | Index 190°C 2,16 kg | ASTM D1238 | 1.3 | g/10min | |||

| Thermisch | Voorwaarde | Standaard | Waarde | Eenheid | |||

| Smeltend | Temperatuurpiek | INTERNE METHODE | 123 | °C | |||

| Vicat | Verzachtingstemperatuur | ASTM D1525 | 116 | °C | |||

Klik hier om TDS voor mLLDPE 1327MD te downloaden

4、MLLDPE 1327MD Pelletdisplay

Op zoek naar hih-kwaliteit metalloceen lineair lagedichtheidspolyethyleen? Bereik oNeem nu contact op en bespreek uw wensen met onze experts!

【Gerelateerde aanbevelingen】

MLLDPE XP9100: Hoogwaardige mlLDPE voor blaasvormen en verpakkingen Meer informatie>

mlLDPE 1018MF: Hoogwaardige MLLDPE-hars voor landbouwverpakkingen Meer informatie>

mlLDPE D174: Hoogwaardige filmkwaliteit copolymeer voor extrusietoepassingen Meer informatie>